Superintendents Corner

3/29/2023

Out doing a little spring cleaning. The snow removal company moved a tremendous amount of rock onto the golf course this year. Thanks to the homemade rotary broom we can put it all back on the road, eliminating the dangers of rock on the golf course. We have also been busy piling sticks up. Thanks to the Iowa Central Golf team for their help, many hands make light work. In the coming days we will begin to pick up the piles as the crew arrives and time allows. We have also complete the first roll of the greens. It was quite the learning experience for the ICCC Turf program. Everybody had their chance at driving this awkward machine. Rolling will help to firm up the greens, so when we drive mowers across them, they do not leave tracks. If mother nature allows, we will roll them one more time this week, and then start to remove the excess sand. Every day the golf course conditions improve, hope to see you out.

3/23/2023

3/16/2023

It may not look like it but in 24 hours the golf course opens for the 2023 Golf Season. Last nights snow was a little more than expected, hopefully the forecast are correct and it will all be gone by this afternoon. Once the snow is gone we can get out and get greens blown off and rolled for the first time. This is also a reminder to get your lawn mower ready for the season, change the oil, sharpen the blade, blow out the air filter, and check the height. See you on the golf couse.

One year ago today we opened the golf course, this year 34 degrees and flurries. This winter has been particularly problematic. Throughout the winter a tremendous amount of ice accumulated on several of our greens. At one point the ice on 18 green was over 4 in thick. Short term this does not present any problems, but long term is a different story. Depending on the condition of the ice it can suffocate the grass and trap toxic gases under the ice. This ice formed around the first of December, and with the long winter, was beginning to be worrisome. So as you can see during the last warm up we took action. After several hours of breaking up ice, 18 green was cleared. Now that it has been a couple weeks it looks like it was just in time. All turf under the ice appears that it will come through without a problem. To help minimize ice problems a black fertilizer is used in the fall right after we close. As you can see in photo on the right the fertilizer melted its way up through the ice, all of the black dots are granules of fertilizer. This fall fertilizer application worked just as it is intended on all the rest of the greens, clearing the ice in a timely manner keeping the greens healthy

Hopefully warm weather is not far away and shoveling snow is a distant memory.

Some new life for Driving Range Tee. Like every Driving range this area takes a lot of abuse. A couple weeks ago we seeded into the worst spots and now we have new life. The nice straight rows are from the machine that we used to seed, called a slit seeder. It cuts a trench in the ground and drops the seed in. This makes a perfect little environment for germination, and it appears that we had a very high germination percentage. In the coming weeks this will continue to fill in and make for a great hitting surface.

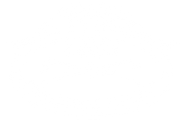

And you thought your water bill was big. From July 16 to August 16 FDCC used almost 4.8 million gallons of water. Unfortunately, this was the highest monthly total ever and makes the total from June 16 to August 16 9.2 million gallons. As a reference the FDCC pool holds about 80,000 gallons of water, which comes out to draining and filling the pool 115 times in the last two months. I can’t wait for snow.

It has been a long time since we have had to make our own swing joint. Back when the irrigation system was installed all swing joint were custom made for each head, new ones now are very handy with O-rings that do not require you to have everything just perfect. The swing joint is what allows us to install and replace irrigation heads and put them at ground level, they are adjustable for height, by swinging up and down. While fixing this head the old boys put the pipe extremely deep into the ground, so the easiest thing to do was make our own. The pipe threader probably has not been used for over 20 years, but worked perfect. Was fun to show the younger crew members how to do, not very common anymore.

It is finally open. 13 Blue tee is back open for play. After closing the tee last fall new irrigation heads were installed, the tee was flattened, and realigned with the green. In the coming weeks the trees on the left side will be trimmed back, greatly improving the shot. It will also allow the entire tee to be used with an unobstructed shot at the green. Funds from the Bill Hird Foundation were used to complete this project.

The weather doesn’t feel like it, but in less than 30 days the pool needs to be filled with water, and in a short 37 days the pool opens, hopefully it will quit snowing by then. The first step is getting all of the debris cleaned out of the pool. A tremendous amount of leaves were in the pool this spring. Now that the leaves are gone we can begin cleaning and patching the liner. In the coming weeks a new chemical control system will be installed, replacing the one that was installed when the pool was built. Watch for updates as progress continues.

A little spring cleaning at the course this week. The other day we had the weather to burn off some of our native areas, hopefully the rest will be burned in the coming days. This is a wonderful way to rejuvenate the area. The black ground will heat up quickly allowing the grass to come back quickly and the fire is intense enough to remove volunteer trees and weeds. This reduces the maintenance required to keep the areas looking good. It is amazing how much heat the grass can generate.

Mother nature has not been very cooperative this year for golf. Opening day was 20 days ago and we are finally putting the first cut on greens. Some of them are very slow to green up, but they are coming. We are also busy fixing irrigation. An uncooperative 4-inch line is finally back together. With the help of a ratchet strap and a mini excavator we got it lined back up so that fitting could be installed. By tonight we will know if it was successful, crossing our fingers.

So what do you think about when you hear wind advisory? As a golf course superintendent the first thing to my mind is trees. High wind and trees make for work and sometimes a lot of work. Fort Dodge Country Club has over a thousand trees on the property. Fortunately the high wind came when there where no leaves on the trees, leaves would have only compounded the damage. Along with the tremendous amounts of stick debris that we have to pick up after this wind event, we have two trees.

The tree in the left photo was an old Mulberry tree and the tree in the bottom two photos was a very old Linden tree. This tree showed no signs that it was hollow, it has about 8 inches of good wood around the outside and the rest is gone. This goes to show always be aware of the trees that you are around, they may not be as good as they appear.

Just a few pictures from yesterday. We started to do the first roll on the greens. Rolling before any play on the greens is essential. After winter the greens are extremely soft. The rolling adds a little compaction to the surface to reduce ball marks, foot traffic, and wheel marks from mowers. In the top right picture you can see that there are a few sticks to pick up yet. Please watch where you are going until we get the golf course cleaned up. A stick lodged in the wrong part of a golf cart can do damage to the cart and the golf course. The picture to the left is a frost heave in 15 fairway. I have never seen the ground rip like that before. Hopefully the pipe underneath is still in one piece, could be an interesting irrigation fill later this month.

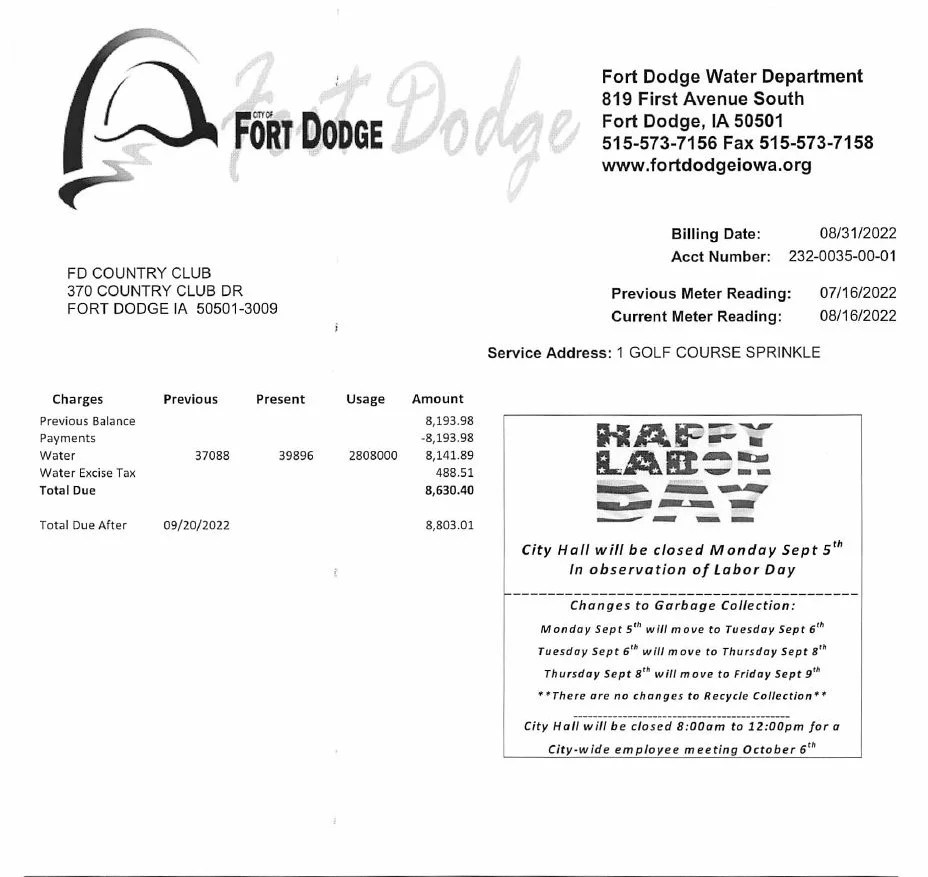

Although it does not feel like it today spring is getting closer. This is a reminder to get your lawnmower out and ready to go. Change the oil, sharpen the blades, blow out the air filter, and wash off the winter dust we will be mowing grass in no time. The last mower that we had to go through was our 10-foot rough mower. We pulled it all apart to see what needed to be fixed and replaced. This year was a new axle, the constant beating of grass blowing on it wore the shaft to the point of replacement. Good for another 7 years and ready to go.

There here, 30 Brand new Ez-go golf carts. Each cart is complete with a windshield, sand and seed bottles, and USB ports. Can’t wait to try them out and see them on the golf course.

The golf season is getting closer by the day and this week new Dr. Range hitting mats arrived. Once the golf course opens, we will put these out behind the range to use. The objective of these new matts is to relieve some pressure from the real grass on the Dr. Range tee. By reducing the hitting pressure on the turf, hopefully it will provide a better experience all season. These new golf mats were purchased by the Hird Foundation, where all donations go to golf course improvements.

July 13, 2021

February 11, 2022

Just wanted to give a quick update on the tree removal here at the golf course. It is hard to believe the amount of lumber that we have accumulated in the last 7 months. In total around 140 trees have been removed from the golf course. All but a small handful have been ash trees, the remaining trees were either dead or a safety hazard and needed to be removed. When this project started, we only had a few trees that showed an infestation of the Emerald Ash borer, now that we have this many trees down, it has become apparent that the infestation was much larger than originally thought. Every tree that I have checked in our pile has the bug crawling around in it. This means that in the next 5 years or so every ash tree on the golf course will be dead. With an estimated 80 trees left there is still a lot of work to do. This means right now we also have 140 stumps that must be ground out, cleaned up, filled back in with topsoil, and seeded. The process of removing the top potion of the tree is only half the work, the rest is yet to come. Fortunately, a majority of the work being done is not by FDCC staff, but employees of Richard Stark. Richard has donated the equipment and finances to get these trees cut down and cleaned up. Thank you, Richard.

Just a quick golf course update. The snow is melting with all of the warm temperatures and the rain last night. As you can see there is a fair amount of standing water. For the most part the ground is completely frozen and the frost has not started to come out of the ground yet. Once the ground starts to thaw the ground will become very soft as the water saturates the thawed ground and sits on top of the frozen ground. Everybody is starting to get cabin fever, but please stay off the greens during this period. They are extremely soft and will easily be rutted or roots sheared off. As soon as mother nature allows, we will get out on the golf course to get it ready for opening, and we will keep you updated as that gets closer. Until then think warm thoughts.

This week we started to work on one of our fairway mowers. This mower is going into its 23 season and has served us very well. This year when we brought it around front, out of the cold, it had oil under the front tire. Upon inspection you can see that a small section of the seal has blown out (photo above). This is what is allowing the oil to escape. This small quarter inch defect makes the machine inoperable until fixed. Upon disassembly of the wheel motor, it appears that the shaft has worn to the point that the seal cannot perform its job. Fortunately, we have a bone yard of old hydraulic motors and other parts. After a couple tries a replacement shaft is found, not new but appears better than the shaft we removed. With a new seal and a replacement shaft we will see if it holds up. Although this is not the ideal way to fix this motor it saves us a couple thousand dollars, a new wheel motor for this machine is $2200, with an unknown delivery date, new seal and free shaft $25.00.

After mowing for 22 seasons the mower heads are also starting to show their age. As you can see in the photo to the right, it has rusted through part of the frame. The rusted-out spot is where part of the lifting mechanism attaches to the reel. With a short section of pipe that we split in half and a little bit of welding, good as new. Hopefully last another 22 seasons.

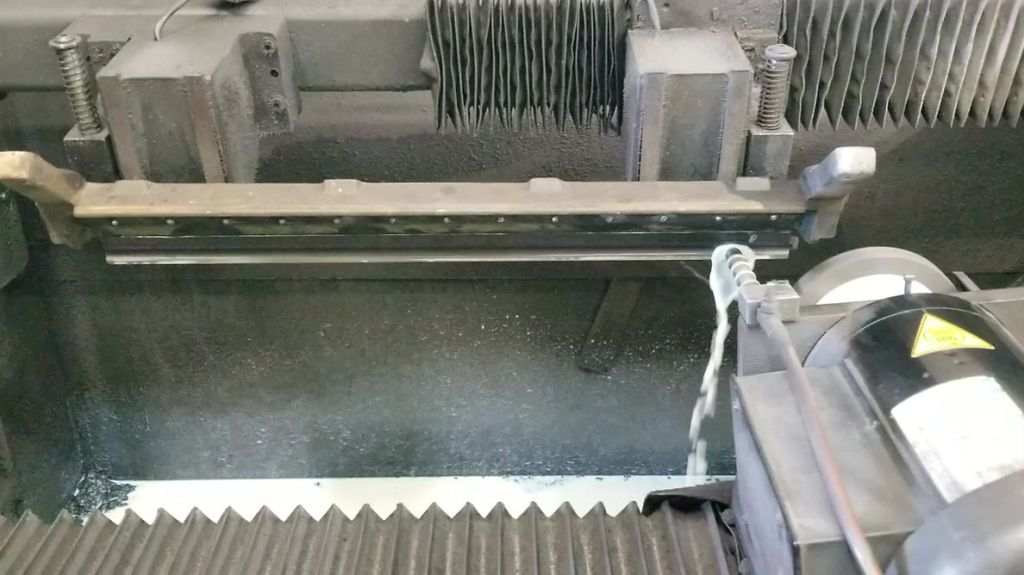

It is the middle of the winter snow on the ground and freezing cold, I consistently get what do you do this time of year. The short answer to that is we get ready for a successful season next year. One of the main items that we do is go through every mower reel that we have. The quality of cut that the mower reels produce directly impacts the quality of your round of golf. The reel pictured to the left is off of a greens mower. In total we have 31 cutting units for the different mowing task on the golf course. So now we are going to quickly go through the steps that we take to take a worn out, dull reel to brand new and razor sharp, ready for the coming season.

The first step is to tear down the reel into all of its individual components. We do this for two reasons. 1. Most of the parts have to come off any way to get it into our grinder. 2. By taking it completely apart it allows us to check all of the bearings and other wear points. We can then replace all worn or damaged parts. Thus, minimizing in season break down. The photo to the right is the completely disassembled reel. It can now be put into our reel grinder. Once in the grinder using dial gauges, we ensure that it is within .001 inches of being parallel to the grinder. Just as a reference a regular sheet of paper is 4 times thicker. This is the precision needed to make sure they cut when done. The video is the grinding process in action, the real time length is just over 2 minutes to grind each blade once. On this particular reel we had to grind each blade 9 times to get them sharp. This comes out to 135 passes that we had to make.

The last piece of the puzzle is grinding the bedknife. The bedknife is what completes the scissor type action to cut the grass. On a greens head the bedknives are replaced every year on tees and fairways they might last several years. Regardless whether the bedknife is replaced or not, when the reel is ground the bedknife is also. Again, they are ground to .001 tolerances. When the reel spins it will cut grass but not touch the bedknife. The video below shows the process of grinding the top of a bedknife. As you watch the video you can see that the grinder does not grind all of the way across on the first pass. Without this grinding the reel will not produce a quality cut. The time required to grind a bedknife depends on how many passes must be made to make it perfetly true.

So what is killing the grass this week? Armyworms. This is the first time that this has happened in this area that I know of. Armyworms are blown up from the Southern states as moths. The moths lay eggs and then we get the destruction. The eggs hatch and the worms are hungry, the little worms can chew through an entire lawn in a night, killing it. Fortunately for us our damage has been sporadic, mainly on a couple tee banks. As you can see in the picture on the right the armyworms have completely destroyed the tee bank, but once they get to areas that we treat for grubs it stops. The chemical that we use for grub control on Tees, Greens, and Fairways provides protection against the armyworms. This destruction is not limited to the golf course, if your yard is turning brown on a large scale you might have these little guys also. Fortunately they are a southern bug, once we get a good frost it will kill them all. We will continue to monitor the situation on the golf course and count our blessing. I have heard of other golf courses losing as much as a third of there rough.

The reel is then reassembled and ready for the season. It is a long process but necessary for a successful season, just 30 more.

A beautiful morning at FDCC

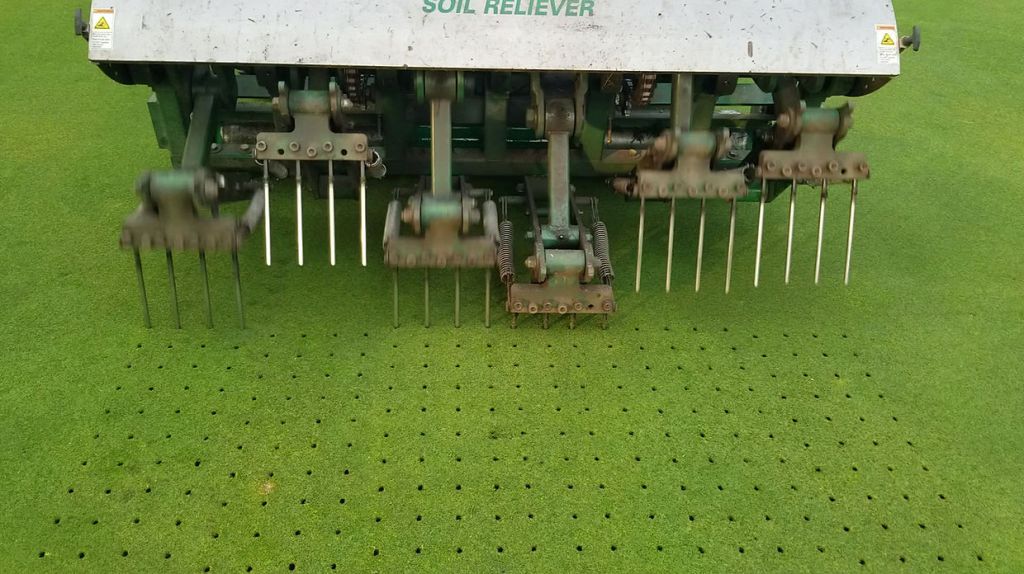

I have had numerous questions on what we do when we aerify our greens. The process that we do is called deep tining. In this process we use a 12mm tine that goes into the ground about 9 inches. During this action the machine slightly heaves the ground breaking up compaction and creating channels through the soil for gas and water exchange. If you watch the video closely you can see the ground moving as the machine moves along. The picture to the right are the greens 7 days later, almost completely healed.

They have moved. Today is the start of a trial with some of our red tee markers. On holes 3, 4, 5, 7, and 15 we have moved the tee markers up to the start of the fairway. For the time being this is where they will remain, but we are looking for your feedback. Do we need to do this to more holes? Let us know your thoughts and suggestions. If these change become permanent then we will make a tee box in this area in the future.

It’s here, yesterday I confirmed the presence of the Emerald Ash Borer on the property. The “D” shaped hole in the middle of the picture is the telltale sign that the infestation has begun. This picture was taken from a tree behind 16 Blue tee. Due to the state of decline the tree is in, it was more than likely infested several years ago. With the borer being in one tree on the golf course it is almost a guarantee that it is in other ash trees on the golf course and probably all of them. Unfortunately the days are numbered for our ash trees. This is the main reason that we have hundreds of trees with caution tape tied around them. A majority of these trees are ash trees and will be removed in the coming years. Once trees are infected with the borer they become a hazard, and also become very dangerous to remove. It is not a question of if the ash trees will die, but when.

1/3

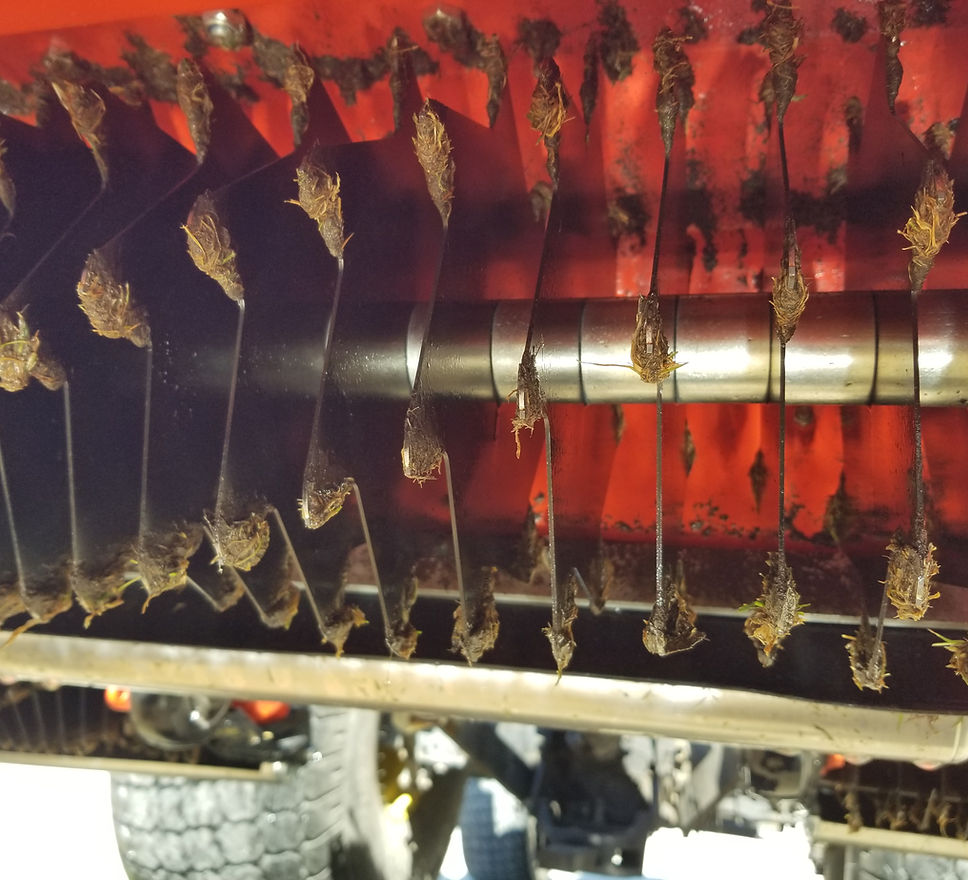

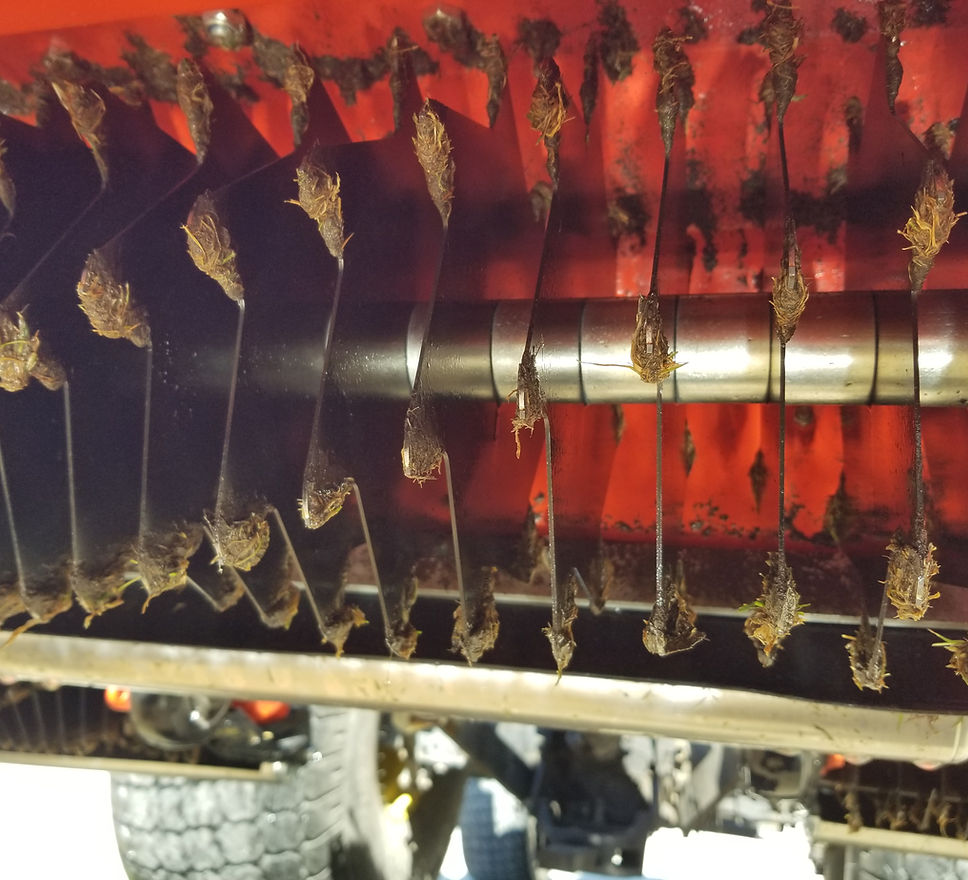

Wiedenmann demo day. Today I was lucky to have Travis Dykstra from Van Wall Equipment and Nick Wood from Wiedenmann. In the video above Nick is running the Triple V 375 verticutter. This is an amazing machine and exactly what the fairways at FDCC need. All of the brown material is dead organic material that is accumulating at the surface. This material acts just like a sponge soaking up water and not allowing it to make it to the roots of the grass plant where it is needed. With continued use of this machine we would firm up the fairways, reduce water usage, and improve appearance. The photo to the left is a picture under the machine, there are 20 carbide tipped blades in each head. The bottom Left photo show what the area looked like after it was cleaned up, but not mowed. The bottom Right is the amount of material removed from about 15,000 sq. feet. Give it a couple days and you will not be able to tell that we did anything. Amazing.

The long process of cleaning and patching the pool has begun. The first pressure washing and scrubbing of the pool occurred this week. Dirt and grime that accumulated during the winter are washed away. It is now easier to find holes that need to be patched in the liner. We will pressure wash the entire pool again right before we begin filing the pool with 80,000 gallons of water. This year we will spend an estimated 36 man-hours pressure washing and scrubbing the pool and pool deck if things go according to plan. We are on track to open Memorial Day weekend, hopefully no surprises are found along the way.

20210512_090429

1/1

20210504_083755

1/1

How does a loaf of bread save the day? When fixing irrigation it is not uncommon for an isolation valve to leak once it it shut off. That is exactly the problem here, a steady, but minor flow of water remained after the valve was closed. The temporary solution to stop the water, which is essential when solvent welding PVC fitting together, is to fill the pipe up with bread. The bread acts like a temporary dam, giving us enough time to weld the fitting and complete the repair. Once the water is turned back on the bread will dissolve and be sprayed out the irrigation heads.

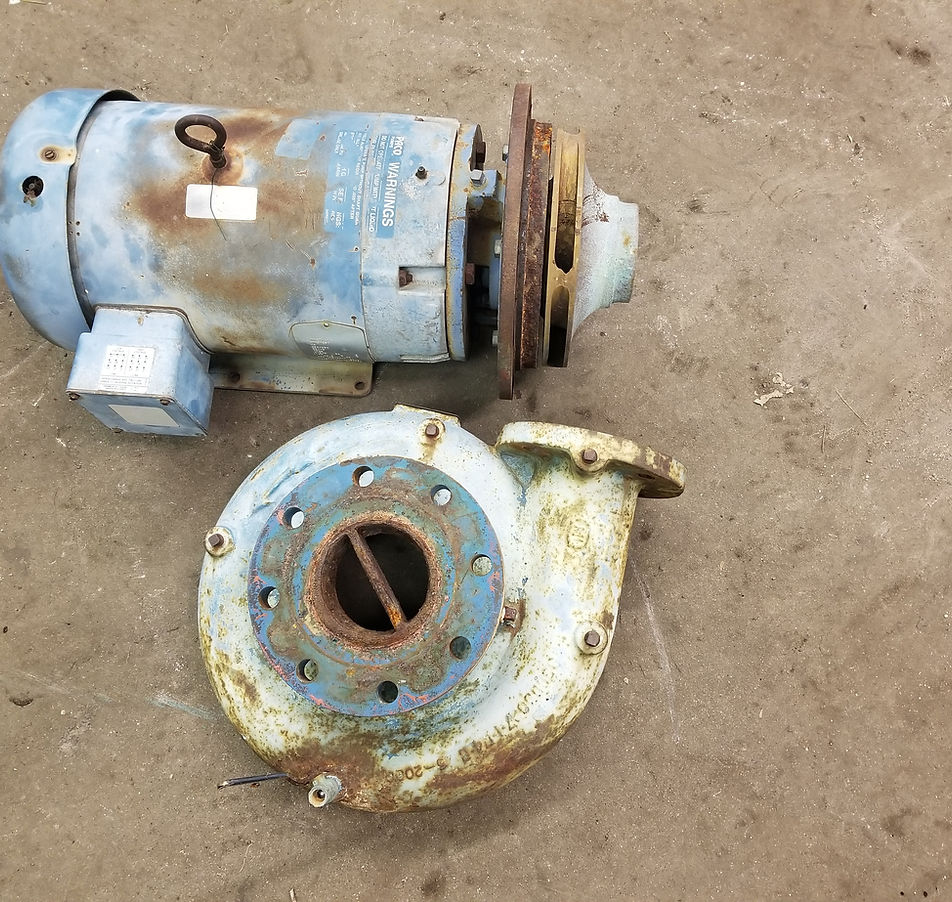

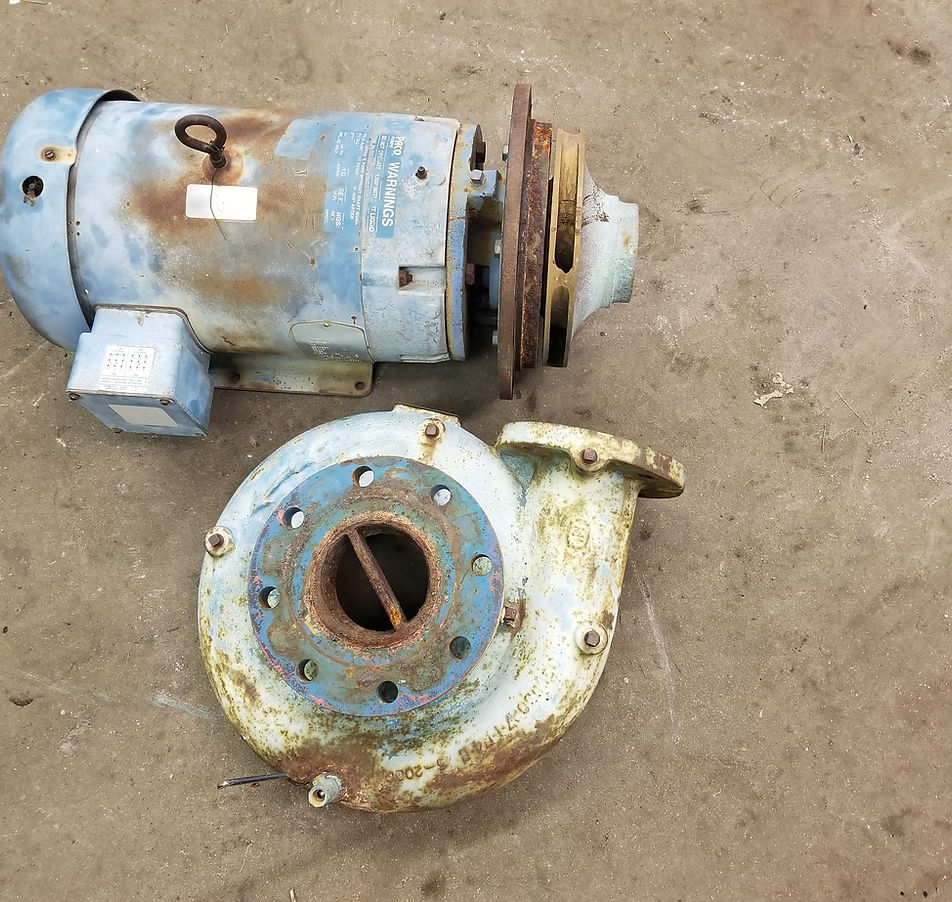

T minus 30 days until pool opening. The brand new pumps are in, they replaced the original pumps from from when the pool was constructed in 2001. The main circulation pump had over 45000 hours. Hopefully these new pumps give us that many hours with no problems. In the coming weeks we will begin cleaning the debris out of the pool and washing it for the first time. Once it is fairly clean we will search for small crack and tears in the PVC liner that need to be fixed. Cracks as small as a quarter of an inch can leak thousands of gallons of water a day. Once the pool is filled there are very few options for fixing a tear in the liner making it crucial that we get them all before water is added. The coming weeks will be busy, with pool preparation.

20210420_141655

1/1

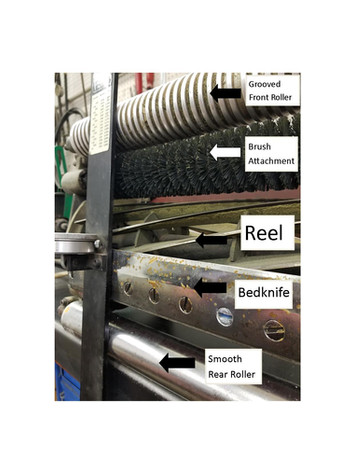

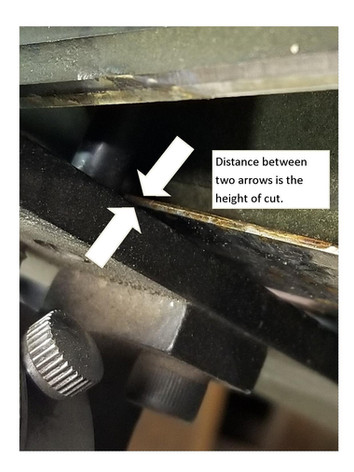

I get the question all of the time “How do Reel mowers work”. So here are some pictures on how a Reel mower operates. In the top left photo you see the bottom side of a mower reel, in this case it is a Toro Greens mower reel. The reel rides on the front and back roller, this is what determines the height that the grass is cut at. The Reel and the Bedknife in combination do the actual cutting off the grass, much like a scissors. The reel spins at high speeds passing very close to the bedknife but not touching. The bottom photo shows how we set the cut. This is a folded over piece of newspaper. As you can see the front edge is a clean cut and the back edge is pulled apart, known as feathering. The reel spins close enough to cleanly cut the first sheet of paper and feather the other. This is why sand and any other foreign material is so hard on mower reels, it is just like taking sandpaper to the cutting edges of the mower and sanding them away. Once the gap is too large between the reel and bedknife it will not make a clean cut, then maintenance must be done to reset the reel and make it cut. In the top left photo it also shows a brush attachment, other attachments can be fitted in this location. This spins with the reels, making contact with the grass and helping stand up the blades so that they can be cut off. The photo on the top right is a close up of how tight we mow the grass. This mower is bench set to .110 inches, roughly the height of two pennies stacked on top of each other. This is a quick overview of how a Reel mower operates, many other factors figure into the setup and actual mowing height of the grass.

20210406_101357

1/1

Always good to get the first fairway mow done. Nothing better then the smell of fresh cut grass.

So what does it take to get the irrigation system up and running don’t you just turn a valve and fill it up? The first thing that we have to do is repair all of the bad heads from the end of last season, this year there was seven. The photo shows a typical head and all of the wire associated with it. Every head on our golf course has two wire running to it. So when you dig up a head there can be numerous wires in the hole going to other heads on that pipe. Due to the age and design of our irrigation system we can not isolate very many parts of the golf course, so it is vital to fix all of the irrigation heads before we charge the system. Once the system is full of water when a head needs to be replaced we have drain thousands of gallons of water to make the repair. Once all known problems are fixed we will slowly add water the pipes, over the course of several days.

20210330_110812

1/1

20210326_141818

1/2

The first mow of the season. It is always nice to get the first cut on the greens, unfortunately it is usually more sand than grass. The picture on the right is a closer view of what is in the bucket of the mower. We will continue to time mowing based on growth, it will not take long and we will be mowing every morning. Until then it will be a balance of cutting grass and picking up sand. The sand is terrible for the mowers, but is vital to the health and playability of the greens.

The first passes with a triplex. What is a triplex, that is the name of the machine that we use to accomplish various task on our greens and tees, most notably mowing. In the picture on the left we are not mowing greens yet, but instead using it to pick up the coarse sand and debris that is on surface of the greens. We do this with a special set of heads known as brush reels. This extra sand is brutal on the mowing reels when we finally mow the greens. The more excess sand we can remove now, the less of a headache it will be later.

20210318_123259

1/2

20210316_081743

1/1

The mowing season will be upon us very soon. Do not forget about getting your mower ready for the job. Change the oil, blow out the air filter, and sharpen the blade. A good sharp blade provides a clean cut, making a healthier plant that is less prone to disease.

It is getting late in the winter but we have one more engine that needs work. The engine out of the bunker rake is in need of help. It was using oil and had very low compression on the left side. We will see what it takes to get it back up and running, hopefully nothing major, and not a complete rebuild that we had to do on the workhorse engine as seen in the photo above. Took it out yesterday and runs great.

20210224_112918

1/2

20210312_084551

1/1

Pool repairs have begun. After 20 plus years of service and over 40,000 hours of operation the main circulation pump is in need of parts.

The first roll of the year. Rolling helps to smooth the green out after a long winter and help firm them up in preparation for mowers and golfers.

20210309_113222

1/1

FDCC-TeeShot-Hole18

1/1

Soon our course will look like this!

Be watching for golf cart do’s and dont’s.

Carts